Sustainability

"The world is a fine place and worth fighting for."

– Ernest Hemingway

For us, sustainability does not only start with the product. As a manufacturer of medical devices, we bear responsibility – for you, for your health and for the world we live in. That is why we focus on environmentally friendly processes, durable materials and resource efficient production. For a healthy future – for everyone.

To reduce our environmental footprint, we have taken the following measures.

Sustainable packaging with grass paper

Our packaging for seat cushions, Heel Protect® and MobiTurn® are made from environmentally friendly grass paper. What makes it special is that the grass used to produce the cardboard comes from previously unused green areas: known as compensation areas. Grass paper protects the environment in several ways: its production requires significantly less water than the processing of recycled paper. It is a biodegradable product and a fast-growing raw material.

Solar energy for production

Since 2012 we use the power of the sun: with four photovoltaic systems, we generate around 250,000 kWh of environmentally friendly electricity annually. This covers 65 % of our own energy needs – and saves the environment around 130 tonnes of CO₂ per year. In this way, we make an important contribution to climate protection and set a good example.

Bee-friendly flower meadow

We have transformed an unused area on our property into a colourful flower meadow – a heaven for bees and other pollinators. Wildflowers grow on the site, providing food and promoting biodiversity. In this way, we do our part to preserve the bee population and other pollinator species.

Climate-friendly Greenline mattresses

Our Greenline mattresses are made from specially developed Ecolast® foam.

The advantage: compared to conventional anti-decubitus mattresses (soft foam mattresses / alternating pressure mattresses) their manufacture causes approx. 22 %*1 less CO2 emissions.

Conventional foam mattress

11 kg foam = 33 kg CO2

Greenline mattress

8,6 kg foam = 25,8 kg CO2

Alternating pressure mattress

10 kg plastic = 35 kg CO2

+ rare earth elements

+ permanent energy consumption

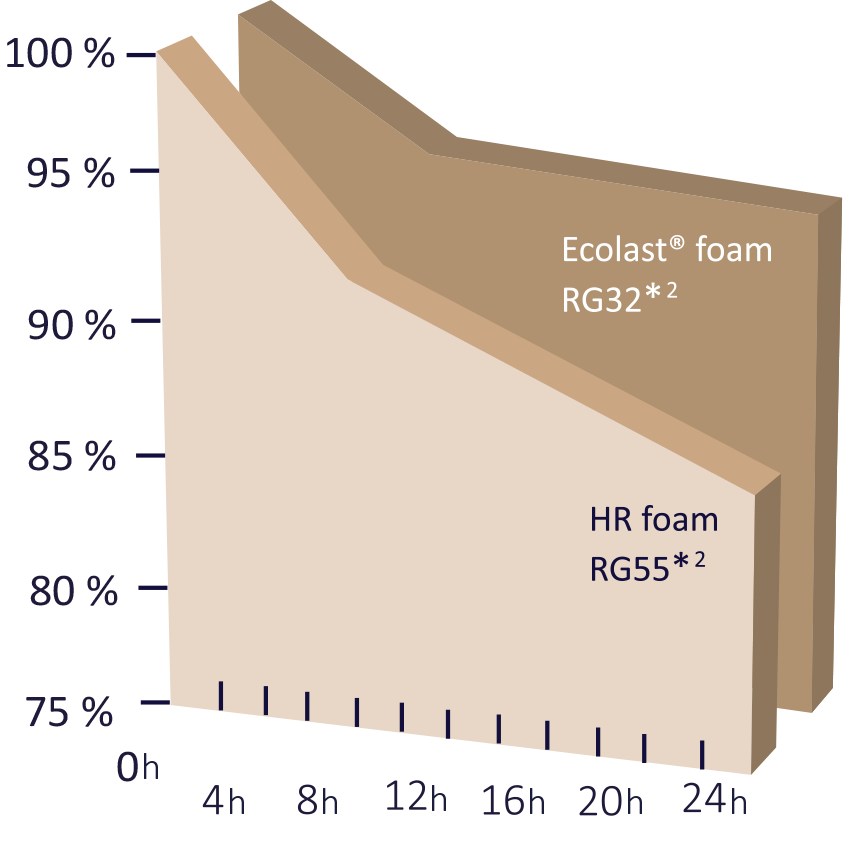

However, the Ecolast® foam offers even more advantages: The innovative hybrid foam has a more open cell structure, which ensures better air circulation and thus creates an optimal microclimate. It also offers excellent pressure relief and greater durability compared to conventional foams.

Hardness loss after exposure to humidity (35°C, 95% RH*3

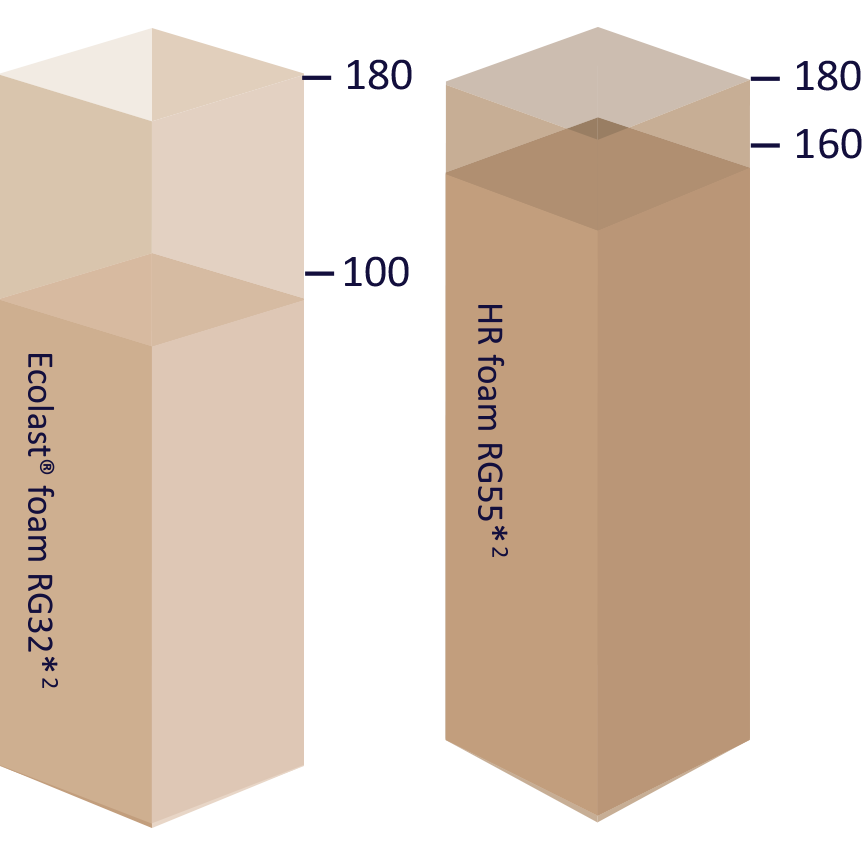

CO2 emission per m3 in kg*1

BeeGood mattress

Each recycled BeeGood mattresses generates approx. 72 % less CO2 emissions in comparison to conventional foam mattresses. When you consider that around 40 million mattresses end up in landfills in Europe every year, it is time for a sustainable solution! Our sister company Deron has come up with a solution: the BeeGood mattress – an innovation that reduces waste and conserves resources. What makes it special is that the bottom layer of the mattress is made from recycled mattress cores. They are shredded and then bonded together. The result is a sustainable mattress – for the people and the environment.

*1 Source: Europur-Study 2015

*2 RG = density (kg/m3)

*3 RH = relative humidity